Mineral and Rock Resource

Ore Deposits

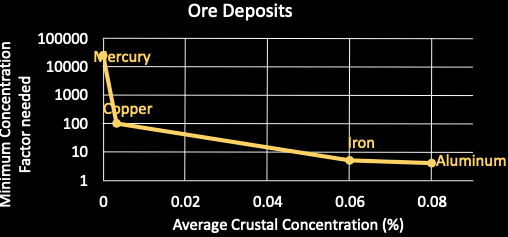

Ore: a rock in which a valuable or useful mineral, usually a metal, exists and is economical to mine

- Concentration Factor

- : Concentration of the metal in the ore

- : Concentration of the metal in average continental crust

- Higher the CF, richer the ore; i.e., less needs to be mined to obtain a certain amount

- Does higher CF mean higher concentration of metal in ore?

- Minimum concentration factor required for profitable mining is inversely proportional to the average crustal concentration

- Exception - few extremely valuable ones, like gold

- But economics dictates what CF is profitable to mine

- $ value per unit extracted vs cost to extract it

- Controlled by supply and demand

- Practicality of mining depends on the mineral storing the metal

- How easy to separate the metal from the mineral and the yield

- Conclusion, the mining industry is volatile

- Mines open and close with demand and pricing

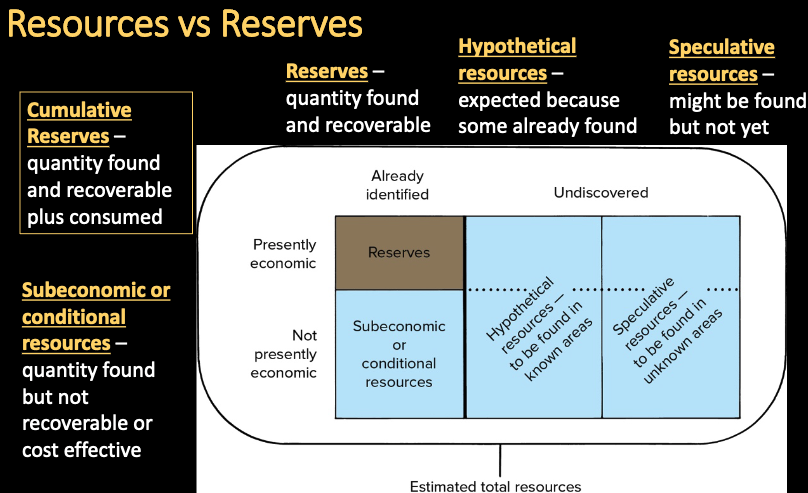

- Ore deposits can move from reserve to sub-economic resource purely based on demand

Ore deposit distribution is uneven

Types of Mineral Deposits

- Igneous Rocks and Magmatic Deposits

- Pegmatites

- Crystal settling

- Kimberlites

- Hydrothermal Ores

- Veins

- Sedimentary Deposits

- Banded iron formations

- Evaporites

- Low-temperature ore-forming processes

- Placers

- Bauxite

- Metamorphic Deposits

Igneous Rocks and Magmatic Deposits

-

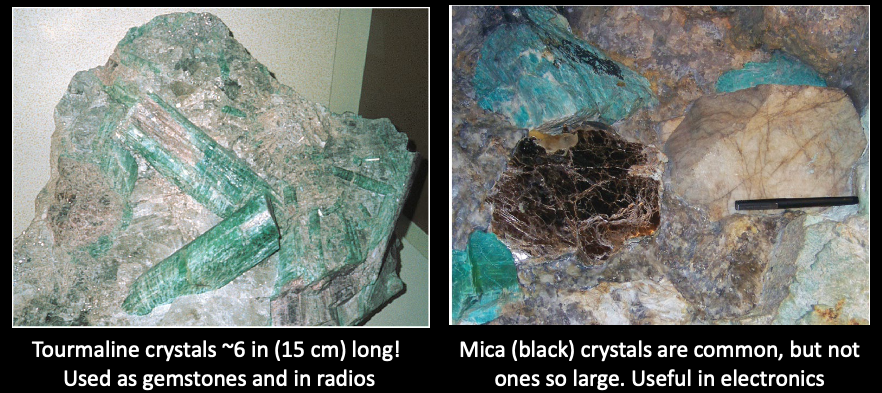

Pegmatite: unusually coarse-grained igneous intrusions (all crystals > 1cm)

-

Can be meters!

-

Feldspars in pegmatite common

-

Used in ceramics and making glass stronger

What does the size of the crystal infer about the duration of magma cooling?

- Gravitational crystal settling: minerals concentrate in cooling magma chamber due to gravity and density an easily mineable layer

Kimberlite

igneous intrusion containing diamonds; cooled at high pressures within mantle and extruded to surface rapidly.

Kimberlites need high pressure to form a diamond and then rapid extrusion to produce finer-grained holding rock.

- Currently, 4 active Canadian diamond mines netting a few billion dollars a year

- First produced in 1990s

- Now in top 5 diamond sales

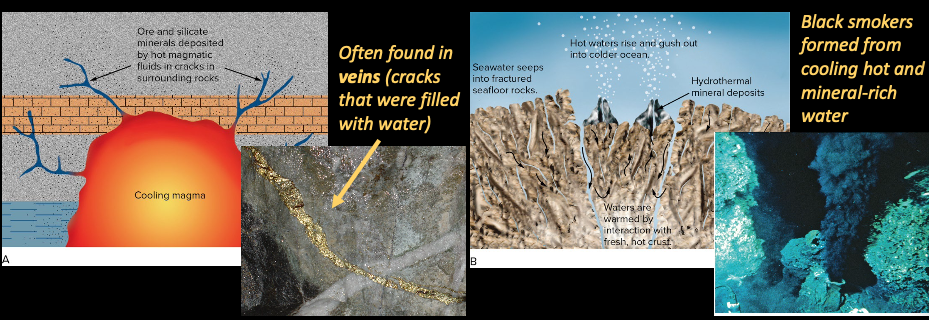

Hydrothermal Ores

Hydrothermal ore deposit

A deposit by (A) minerals dissolved in fluids that escaped from magma, seeped into cracks in surrounding rocks, leached those minerals out and cooled

- or (B) seawater circulating through fractured seafloor, being warmed and leaching minerals, then coming out of the seafloor and cooling upon hitting the cold seawater

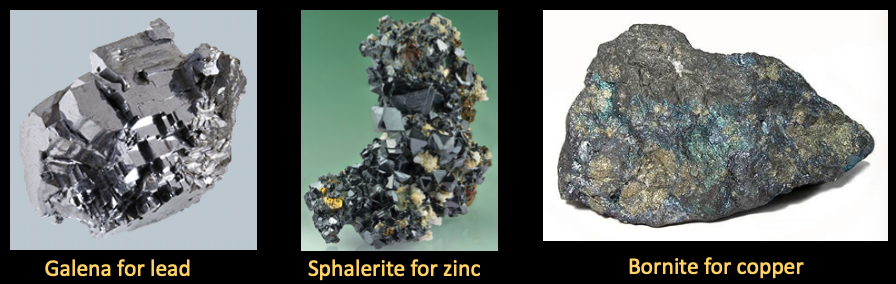

- Many of our metals found in hydrothermal deposits

- Often in sulfides because magmatic gases and fluids contain sulfur

- Lead from Galena (PbS)

- Zinc from Sphalerite (ZnS)

- Copper from Bornite (CuFeS2), CuS, Cu2S (cooper-iron sulfides)

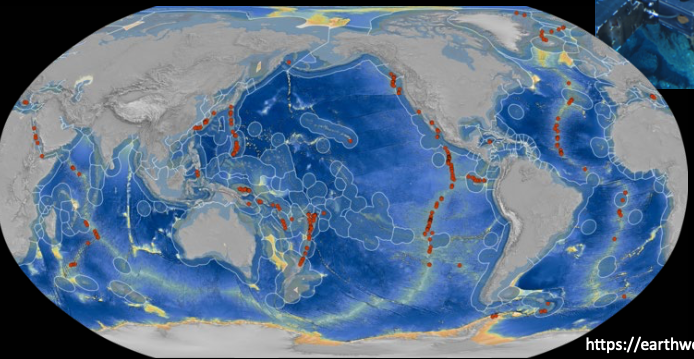

- Hydrothermal and igneous deposits often located along plates boundaries, especially subduction zones

- Mining the seafloor and hydrothermal vents?

- US, CA, Japan, AU, China India, Brazil, Singapore, Russia, Germany, UK moving on with plans Many countries have potential seafloor minerals with their Exclusive Economic Zones (EEZs)

Sedimentary Deposits

- Some from chemical sedimentary rocks

- E.g., Banded Iron ore/formation is a rock with alternating layers of ironp-iron hematite or magnetite and silicates or carbonates; Ancient evidence of the oxygenation of our atmosphere

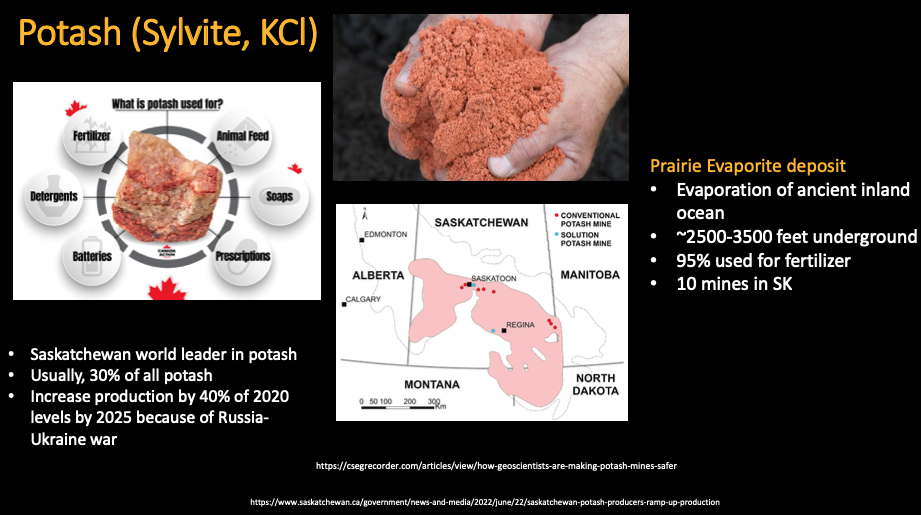

Evaporites

Deposit formed when an ancient body of water evaporated and left behind precipitates

- E.g., Halite (table salt); Gypsum (plaster)

Low-Temperature Ore-Forming Processes

Placers

After minerals are weathered out of local rocks, transported by streams, and mechanically concentrated by the water.

- E.g., Gold, diamond, tin oxide

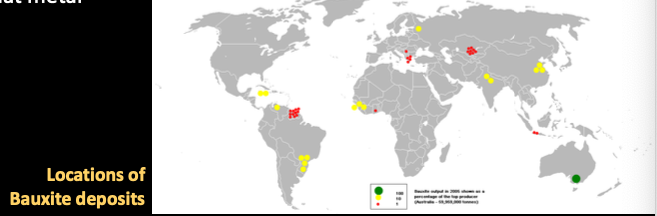

- Bauxite is our main source of aluminum

- Formed by weathering of lateritic soil

- Typically found in tropics with heavy, persistent rains

- Weathers rock/soil, moving mobile elements away and leaving behind heavier, non-mobile ones

- E.g. resulting soil is enriched in aluminum or iron

- When sediment dries up and compacts it becomes a mineable deposit of that metal

Metamorphic Deposits

- Heat and/or pressure of metamorphism produces deposits

- Graphite (pencil lead) formed from metamorphism of coal

- Garnets common in metamorphic rocks

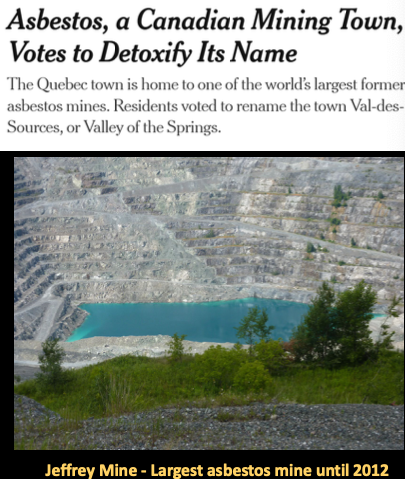

- Asbestos: group of fibrous silicates formed from metamorphosed igneous rocks rich in ferromagnesian minerals and water

Mineral and Rock Resource Examples

- Metal

- Iron - most heavily used metal and most commonly found

- Iron-banded ore, laterites, magnetite in igneous rocks

- Aluminum - second most widely used

- Plentiful in crust but hard to extract; Mostly from bauxite (laterite)

- Copper, lead, zinc, nickel, cobalt

- Common in sulfide ore deposits but also in sedimentary ones

- Gold, silver, platinum

- Common in igneous or hydrothermal ore deposits

- Often a by-product of mining more abundant metals

- Nonmetallic Minerals

- Sulfur - by-product of mining sulfides - for sulfuric acid in industry (acid rain)

- Halite, gypsum from evaporites

- Phosphate rock and potassium-rich potash are evaporites mined for P and K for fertilizer

- Clays - useful in construction materials

- Rock resources

- Most abundant quantity of earth resources we use!

- Why?

- Includes sand, gravel, limestone, quartz-rich sand, marble, granite, and sandstone

- Used for construction, cement/concrete, glass, fracking, and decoration

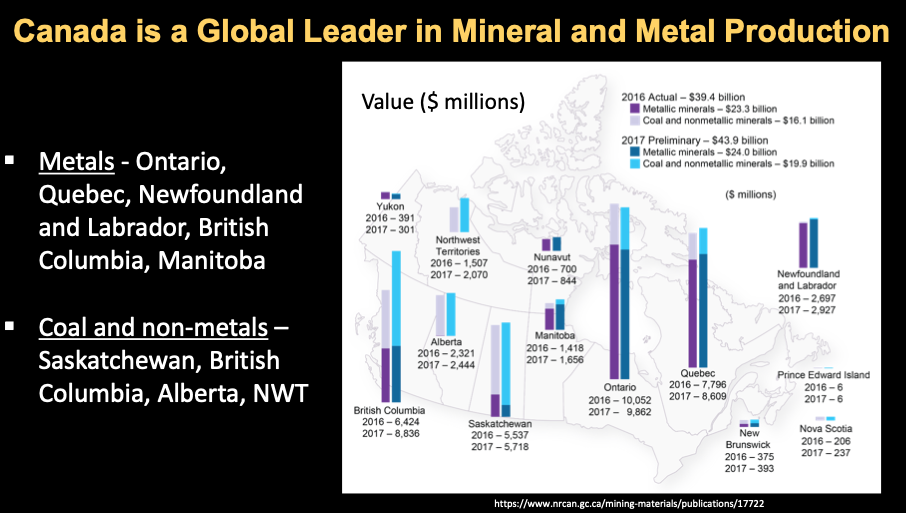

Mineral Supply and Production

- Supply increases only with discovery of new locations or new technology

- Production of most used metals has increased globally

- Even though prices stagnated the last decade, production remained high

- Usually, production is dictated by demand

Mineral Demand

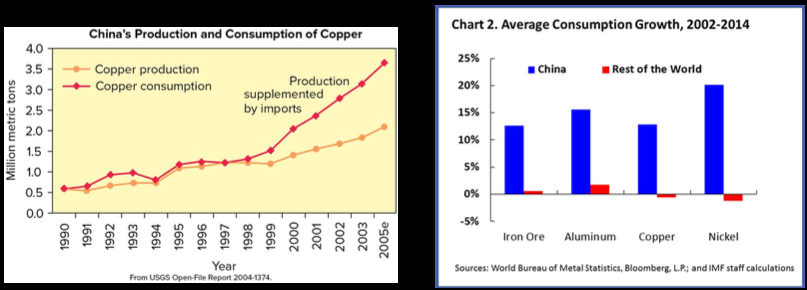

-

Many mineral and rock resources used in construction, industry, and electronics

- Demand increased rapidly from WWII onward with dips during some recessions

- Demand is increasing more because of ambitious nations, like China

-

China ‘consumes’ 40-50% of world’s aluminum, copper, steel & 2/3 of the iron ore

- Because of increasing living standards and because the economy focuses on converting resources into manufactured products

- Also look at demand on a per capita basis, although this does not always give an accurate picture because countries may import resources that they do not need just to maintain relationships

Average American consumes >3 million pounds of resources in their lifetime

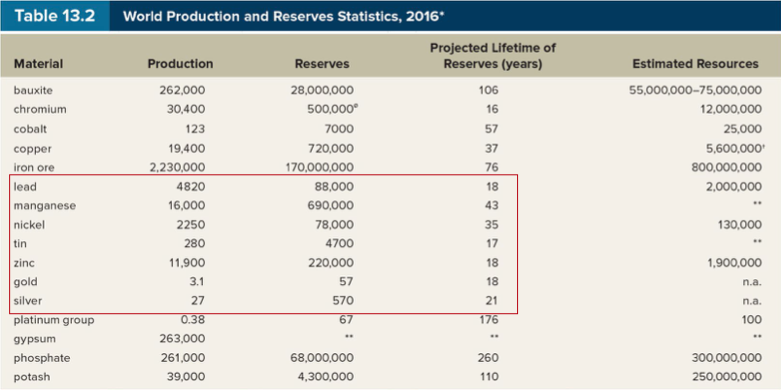

World Supply and Demand

- Assuming constant 2016 demand, some reserves will only last a few decades

- But this is a difficult and almost silly exercise because it is a volatile market

Conflict Minerals

- Dodd-Frank Act (2010, USA) requires companies to report their use of conflict minerals from the Congo and do their ‘due diligence’ to make sure they are not funding armed regimes or human rights abuses

- China followed in 2015 and EU in 2017

Canada voted against a national act in 2014 under a conservative government but claims to follow OECD guidelines.

OECD: Organization for Economic Co-operation and Development

Mineral Futures

- Mineral and rock resources are essentially non-renewable

- Consumption >>> Reuse rates

- 1950 ⇒ 2000 population grew by but consumption by

- Means to increase supply

- Decreasing supply drives up costs and opens up subeconomic reserves

- Improvements in processing technology

- Continued exploration

- Reduce consumption rates

- Large developing nations need access to resources to grow

- Consider car ownership: In 2016, 797 vehicles per 1000 people in USA

- Only 154/1000 in China and 167/1000 in India

Mineral Exploration Methods

Need to consider new ways of detecting and mapping minerals in the Earth

- Geophysical prospecting

- Identifying changes in density, radioactivity, magnetic or electrical properties of subsurface rocks

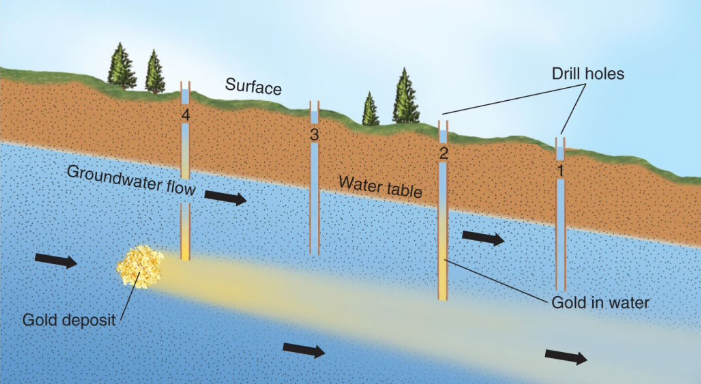

- Geochemical prospecting

- Locating geochemical clues in surrounding soil, plants, groundwater or soil gas

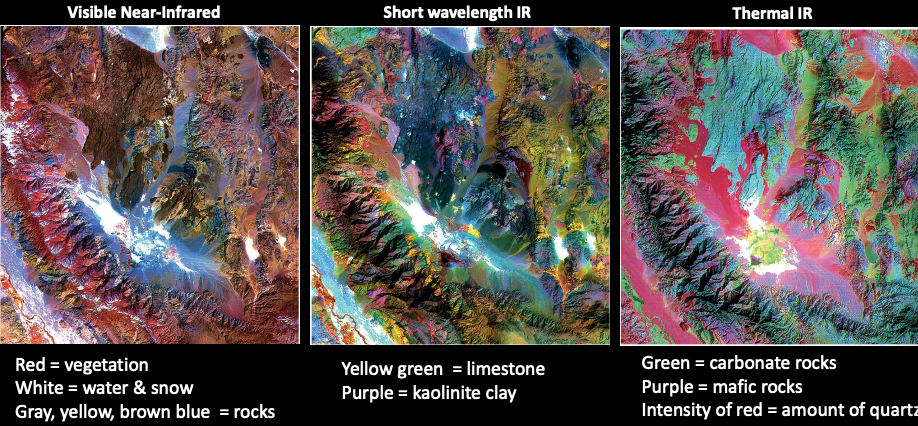

- Remote sensing

- Detecting wave-transmitted energy, like light or infrared radiation via aerial or satellite imagery

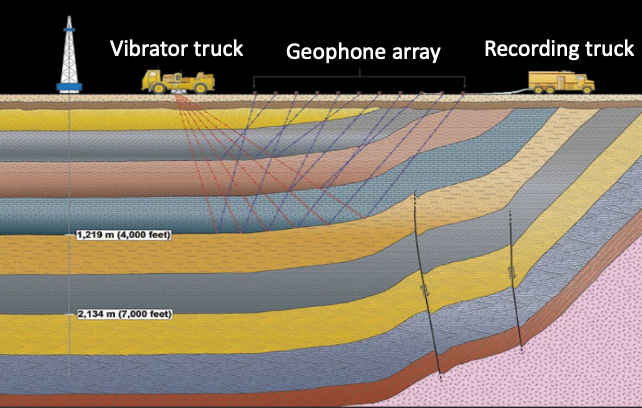

Geophysical prospecting

- Seismic surveys: use explosives or vibrator truck to create a seismic wave and record the returned wave

- Time and shape of returned waves recorded by the geophone array will reveal subsurface layers and structure

- Drilling still needed to confirm what was found with the seismic survey

Look for chemical leached in groundwater by sampling a series of wells:

Remote Sensing

Combining satellite imagery with ground truthing information is best

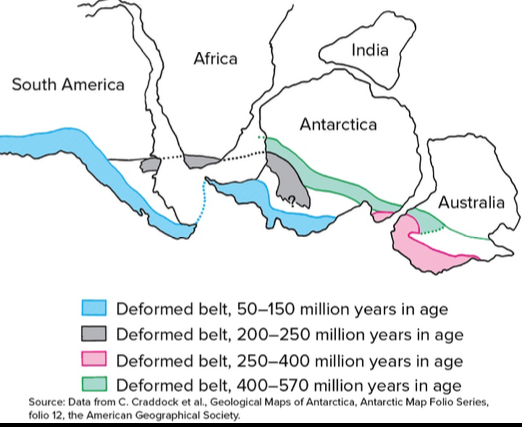

Advances in geologic understanding

Understanding of plate tectonics provides clues as to where new deposits may be

- E.g., molybdenum occurs above subduction zones

- E.g., Antarctica may contain significant ore deposits because the continents were one giant land mass at one time and mountain belts of ore deposits from an ancient range appear on several other continents

Antarctica falls under international treaty to be clear of resource exploration or recovery

Marine Mineral Resources

- Seawater contains almost every chemical element but in small quantities

- Continental shelves were once above sea level and placer deposits from streams are possible

- 10% of world’s tin (Sn) is from offshore placer deposits

- Titanium, zirconium, and chromium are also potentially economically viable

- Hydrothermal ore deposits

- Red Sea – copper, lead and zinc from exploratory dredging

- Sulfides off of Japan and soon in the south Pacific

- Manganese nodules – 10 cm diameter lumps that contain Mn and copper, nickel, cobalt, platinum and other metals found in very deep ocean where sedimentation rates are extremely low

Mineral Conservation

-

Substitute one mineral with another ⇒ shifts shortage problems

-

Replace with non-metals ⇒ but typically petroleum-based plastics, which are bad for environment and petroleum is also limited

-

In many products, it is difficult to substitute metals with other types of materials because of their unique physical and electrical properties

-

Most effective conservation method is recycling and it…

- Reduces waste

- Reduces mining disturbance to environment

- Reduces energy and fuel consumption

- Reduces greenhouse gas emissions

-

Issues with recycling

- Must be a particular size to be economical

- Difficult to isolate materials in intermingled, complex equipment

- Alloys are mixes of minerals, sometimes made for specific applications (e.g., steel), and need dedicated separation and recycling practices

-

Not all materials are recoverable (e.g., potash and phosphorus in fertilizers, road salt)

Most progress made with metal recycling and with cars ~95% of end-of-life vehicles are recycled in USA and Canada

Mining Impacts

There are four main mining methods:

- Underground

- Miners need to go underground

- Surface (quarries, open pit, & strip mining)

- Dig downward with open top

- Placer

- In stream beds (commonly by dredging)

- In-situ mining

- Dissolving leached minerals and pumping to surface

Underground mines

- Mostly minimal impact on surface, except near opening

- Collapses can occur, especially if mine was long forgotten about

Surface mines

- Visual impacts are obvious, huge, and not reversible

Acid mine drainage

- Sulfuric acid runoff from sulfide ore mines (e.g., common metal ores)

Reclamation of land impacts from strip mining

-

Spoil banks (piles of waste)

-

Loss of vegetation

-

Regrade Spoil Banks

-

Seeding and Revegetation

-

We only wantt to remove the economically extractable minerals from the ore

-

Mechanical and chemical separation of minerals: pulverise rock and chemically treat to remove target elements - What is left behind is called Tailings (i.e., the slurry of pulverized rock and chemicals)

-

Lead to acid drainage and chemical leaching (e.g., mercury, arsenic, cadmium, uranium)

-

Runoff must be collected – tailings ponds

-

Chemicals used in processing often hazardous

- Mercury and cyanide in gold mining

- Smelting (applying heat to ore) releases arsenic, lead, mercury and gases (e.g., acid rain)